Operating system: Windows, Android, macOS

Group of programs: Business automation

Quality control of repair

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

How to buy the program?

View a screenshot of the program

Watch a video about the program

Download demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

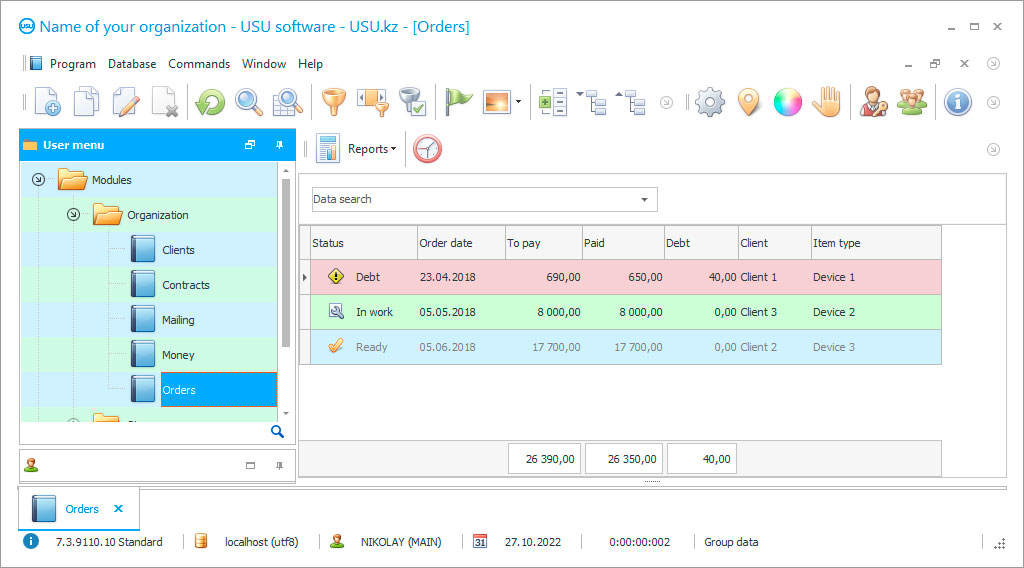

Program screenshot

Quality control of repair in the USU Software system is carried out taking into account the generally established tolerances and standards that the company performing the repair uses when performing work operations, which are presented in the industry-specific reference base built into this software configuration. Based on the norms and requirements for all operations carried out, their quality is determined - the correspondence between what has been done and how it should be done. This compliance is subject to automated control, which makes it possible to quickly assess the repair work carried out in the apartment or on the locomotive.

Thanks to the quality of such control, which is very high, because there is no subjective factor, both the apartment and the locomotives can boast of excellent repair. It should be noted that the configuration for quality control of repair is universal and carries out both quality control of repair of locomotives and quality control of apartment repair. We specifically give two such incompatible objects for repair, locomotives, and an apartment, as an example, to show that the proposed program copes with the quality of work in any field of activity, if it is repair, or rather, with quality assessment and control over it.

So, if we talk about the configuration for quality control of the repair of locomotives, you need to use traditional quality control, when, after the repair, there is a regular check of the operability of the locomotive through its inspection, carrying out technological operations to identify defects and defects, as well as bench tests of the equipment installed on the locomotive. The results of such inspections, inspections, and tests are subject to registration in a journal called the locomotive repair book. Approximately the same, but not all the same, is offered by the configuration for quality control of the repair of locomotives.

Who is the developer?

Akulov Nikolay

Expert and chief programmer who participated in the design and development of this software.

2024-05-24

Video of quality control of repair

This video can be viewed with subtitles in your own language.

If we talk about quality control of apartment repair, then, in this case, an electronic journal is also kept, traditionally called a repair diary. Here, employees, each time add information such as the date of departure to the apartment, which was purchased, according to an estimate compiled (automatically), necessarily confirmed by a check that was brought into the apartment, what you should pay attention to. Quality control of apartment repair is aimed at improving living conditions, and the results depend on the quality of the purchased building materials, the quality of the work performed in the apartment itself, and the standards for the use of these building materials. As it happens, not less, but exactly in the amount as indicated in the regulatory reference base for the renovation of apartments. In the same way, when monitoring the quality of repair of locomotives, the operating parameters of individual units are indicated in the log to detect abnormal heating, noise during their operation before installation on the locomotive and after during its operation - during the period covered by the warranty.

The configuration for quality control (for locomotives, apartments, everything else) has a simple interface, easy navigation, and an understandable menu, so workers with a zero level of user skills can work in it. It is so easy to understand and, thus, to master. The duties of employees include only adding a report to their electronic journals on those operations that were performed by them as part of their responsibilities, the results obtained in the course of these operations. Everything else is already the responsibility of the control program, which collects the information contained in them from all the logs, sorts them by purpose, and forms from them an aggregate indicator as a characteristic of the work performed. Then compares the result obtained upon completion of the work with the planned indicator calculated taking into account norms and standards, revealing the deviation between them.

If the deviation goes beyond the specified error, the control program signals this in color. Since all orders being executed for both locomotives and apartments have their own expression, operational, and cost, in the orders that make up the order base (repair activities). In this database, each application has its status and color to it, which admits the operator to visually control its execution, including the timing, stage of readiness, and compliance with what was stated in the application. If something deviates from the norm, the status color changes to alarming red to attract attention and, accordingly, solve the problem. Such control in the format of color indicators is convenient because it saves staff time without attracting attention to anything until an emergency situation develops.

Download demo version

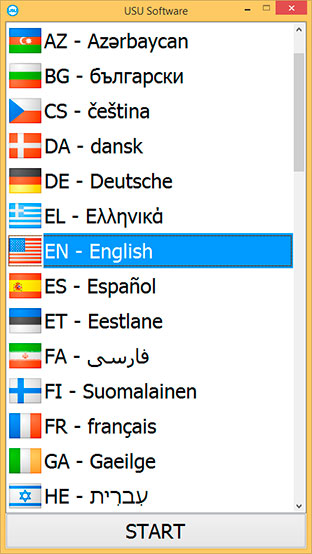

When starting the program, you can select the language.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

Moreover, the statuses and their color change in the control program automatically - based on the results that the workers indicate in their electronic journals since it is from them that the overall result is compiled. This division of responsibility ensures the reliability of working readings because everyone is responsible only for their own area - when entering data, they are marked with the username, so it is not difficult to find out who is registering what.

The program independently forms the documents of the enterprise, relieving personnel from duties, and all of them are accurate, meet all the requirements, the official format. Such documents include financial statements, specifications for the order, waybills, route list, standard contract, applications to suppliers, receipts, the act of acceptance of the transfer. The built-in normative and reference base is regularly updated, automatically updating the standards and requirements for reporting, its formats, if any edits were adopted.

Automated warehouse accounting instantly writes off stocks from the balance when transferred to the workshop or shipped by the client, as soon as the system receives confirmation of such an operation. The company always receives a report on the current inventory balances in the warehouse, a message about approaching a critical minimum, an application with a pre-calculated purchase volume.

Order a quality control of repair

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

The program will be installed

If the program is purchased for 1 user, it will take no more than 1 hourBuy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

Quality control of repair

Continuous statistical accounting allows acquiring exactly as much stock as the company needs for the period, taking into account the turnover of each item. The accumulated statistics allow you to conduct rational planning without unnecessary costs. Moreover, the costs of storing stocks are reduced, which allows reducing their cost. The company is always aware of cash balances in any cash desk and bank accounts - the system generates registers of financial transactions, calculates the turnover as a whole and separately by points. The report on the warehouse compiled at the end of the period shows the demand for all items, the level of consumer interest, identifies illiquid and substandard products.

The financial report drawn up at the end of the period shows what the most funds are spent on, assesses the feasibility of all expenses, and identifies overhead costs. The personnel summary gives an assessment of its effectiveness, showing how much work was done in general and separately by each, how much time was spent in total, who brought the most profit. The summary of customers shows their activity by period, choosing from them those who spent the most, who ordered the most, who brought the most profit and for what exactly. The marketing code shows which sites are the most productive in promoting the company's services compare to the funds invested in each site and the profit received. Analytical reports are presented in the form of tables, graphs, and diagrams with visualization of the importance of indicators in the formation of profit, identify the factors influencing profit. The program’ control automatically performs any calculations, including the accrual of piecework remuneration to personnel, the calculation of the cost price, and the cost of orders according to the price list.