Operating system: Windows, Android, macOS

Group of programs: Business automation

Material inventory management

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

How to buy the program?

View a screenshot of the program

Watch a video about the program

Download the program with interactive training

Interactive instructions for the program and for the demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

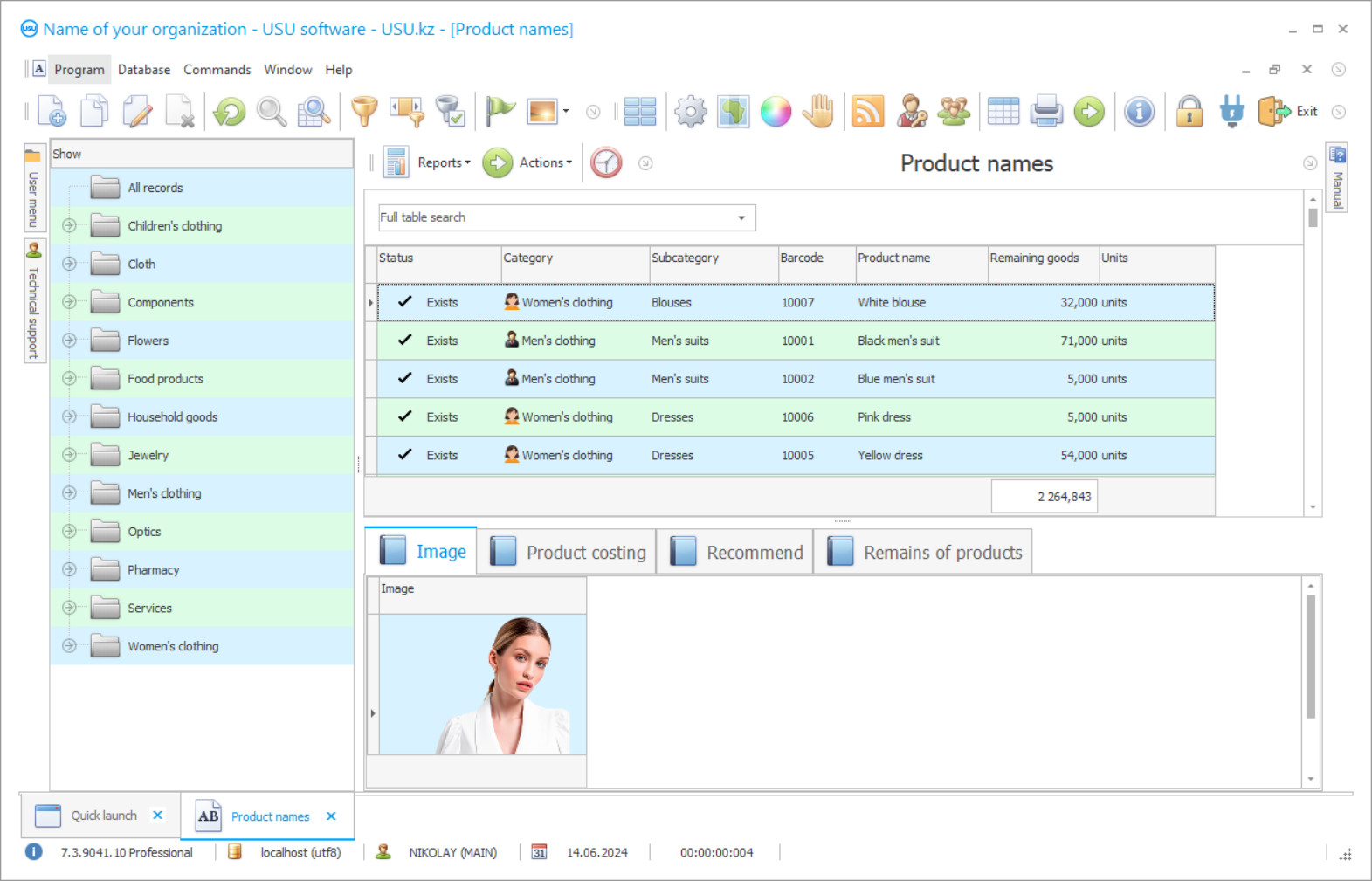

Program screenshot

Material inventory management in the USU Software automation program is carried out automatically, which means that inventories are under the control of the program, which provides promptly current information to enterprise management. Based on it, the management apparatus makes strategic decisions regarding the supply of the next batch of materials to the warehouse or a change in the timing of their receipt for the reason that the material stocks are quite sufficient for the planned period of uninterrupted operations at the moment.

Material inventory management in the warehouse allows optimizing storage volumes and minimizing procurement costs. Since, thanks to automated management, not only a rational placement of materials in the warehouse are carried out, but also compliance with all storage conditions, which allow you to keep materials in a good condition, and reduce the volume of substandard which takes place in case of inadequate maintenance of inventories.

Who is the developer?

Akulov Nikolay

Expert and chief programmer who participated in the design and development of this software.

2024-05-04

Video of material inventory management

This video can be viewed with subtitles in your own language.

Inventory management of configuration performs the function of real-time management based on changes in performance indicators, which is reflected in their state as the primary and current data collected by personnel during the performance of duties - acceptance of materials upon delivery to the warehouse, transfer, transfer to production. The staff, fulfilling the current duties in the warehouse, registers the work performed in work logs, which are personal to each - to limit the area of responsibility, from where the data sampling comes from. Carried out by the configuration for the inventory management, along with its sorting by purpose and the subsequent formation of new values for the indicators. Any movement of materials in the warehouse is documented by invoices, which are generated automatically when specifying the names, quantities, and grounds for movement. Each of them is registered in the inventory management configuration with the assignment of a number and compilation date, status, and color to it to indicate the type of transfer of inventories. Invoices are saved in a separate database, which is the subject of analysis to assess the demand for materials - the inventory management configuration performs it automatically at the end of each reporting period, presenting the results to the management apparatus for decision-making. The color of the statuses visually separates the base, which is constantly growing, since the warehouse is constantly functioning, accepting materials for storage and transferring them on demand.

Material inventory management should serve such purposes as providing a continuous flow of required materials, parts, and components for efficient and uninterrupted flow of production. It also stands for minimizing investment in inventories keeping in view operating requirements, providing for an efficient store of materials so that inventories are protected from loss by fire and theft, and handling time and cost are kept at a minimum. Material inventory management should keep surplus and obsolete items to a minimum.

Download demo version

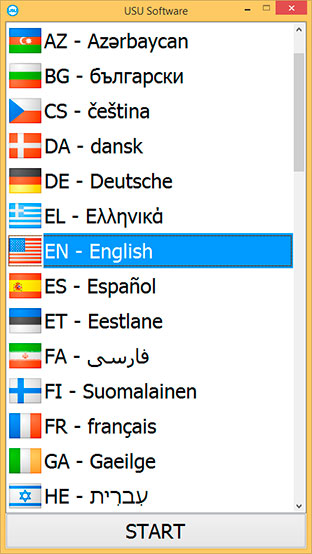

When starting the program, you can select the language.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

Instruction manual

It might seem obvious that material inventory control is efficient as long as the material level is going down. Materials should increase or decrease in amount and time as related to sales requirements and production schedules.

Responsibility for the inventory of materials is that of the top management, though decisions in this regard might well be based upon the combined judgment of the production manager, controller, the sales manager, and the purchasing manager. This is desired in view of the financial considerations involved in the problem and

Order a material inventory management

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

The program will be installed

If the program is purchased for 1 user, it will take no more than 1 hourBuy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

Material inventory management

also because of the need for coordinating the different kinds of materials and conflicting viewpoints of different departments. For example, the sales manager, purchasing executive and production manager usually favor, though, for different reasons, the policy of carrying a larger amount of stock whereas the financial manager will prefer to keep investment in the material at the lowest possible level. However, in a large number of organizations material control is generally made the specific responsibility of the purchasing department.

Material inventory management is an incredibly important process in business. This process must be put under reliable control. To do this, you will need specialized software created by experienced programmers from a company called the USU Software. Material management will be carried out seamlessly, and employees will appreciate the increased level of office management. Every individual specialist will be able to carry out the professional duties more quickly, which means that your company will come to success faster.

If the company is engaged in management accounting for inventory, it will be difficult to do something without the USU Software. The complex product operates in a multitasking mode and solves a variety of dilemmas facing the corporation in an automated manner. It is very convenient because you do not have to waste your time on boring and routine calculations.

Our application will perform all the necessary actions quickly and will not make any mistakes. In addition, the USU Software will monitor the activities of the staff and point people to the errors that have occurred. The complete material inventory management solution is fast and provides a huge range of options that you can easily master in seconds.