Operating system: Windows, Android, macOS

Group of programs: Business automation

Maintenance and scheduled repair system

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

How to buy the program?

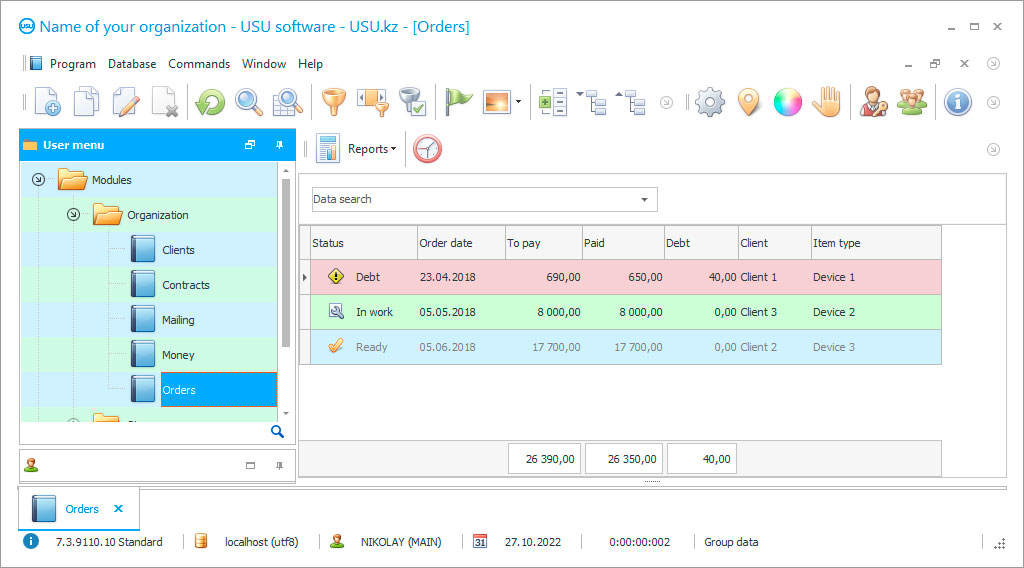

View a screenshot of the program

Watch a video about the program

Download demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

Program screenshot

The system of maintenance and scheduled repairs is a configuration of the USU Software and automates business processes, accounting and control over maintenance and scheduled repairs at an enterprise, whose specialization is the same maintenance and scheduled repairs of various technological objects that may be the property of the enterprise itself or be owned by others.

The system of maintenance and scheduled repair is a universal program. Therefore, it can work with any property rights to objects, the key factor is its specialization in the repair of any equipment. Maintenance usually includes regular preventive and minor repairs, scheduled repairs are activities aimed at larger-scale work, which can be both current and capital, the key word here is planned, so it is carried out in a pre-planned timeframe and with the planned scope of work according to the recommendations presented in the normative technical documentation attached to each facility and embedded in the industry reference base, which, in turn, is built into the system of maintenance and scheduled repairs.

Such reference information, which is always at hand, helps the company to plan the timing of maintenance, observing the frequency of its implementation within the framework of the standards stated in the database. In the same base, indicators of the performance of objects are presented, considering their ‘age’, mode of operation, conditions of detention, for which a scale of special correction factors has been formed, it is the reference to these standards that allows us to assess the quality of the maintenance and planned repairs carried out by the enterprise.

Who is the developer?

Akulov Nikolay

Expert and chief programmer who participated in the design and development of this software.

2024-05-18

Video of maintenance and scheduled repair system

This video can be viewed with subtitles in your own language.

First, the system forms a database of objects that are subject to maintenance and planned repairs, collecting information from a documentary base consisting of contracts of the performance of work, if the objects are not the property of the repair company, inventory lists, if they are located on the territory of the enterprise, delivery notes for these objects, reports on their launch, subsequent maintenance, and operating conditions. As soon as the base is formed by the system of maintenance and scheduled repairs, the drawing up of a schedule begins automatically, where the individual characteristics of each object and its importance in the production process are considered in order to minimize the periods of maintenance and scheduled repairs since any downtime of the equipment affects the profitability of the enterprise. The plan specifies the operations of each facility and each procedure, including maintenance and scheduled repairs, considering the current state of the facility and its operating history.

In addition to the standards proposed by the reference base for the implementation of these procedures, there is a qualification of the service personnel who leaves recommendations after the next maintenance and planned repairs in order to consider the deviations from the official standards and performance indicators identified at the facility - these remarks should be also included when carrying out new inspections. To post such information, users use personal work logs, where they leave their conclusions about the work done, record its results. The system of maintenance and scheduled repairs independently collects this information from all logs, sorts them according to their intended purpose, and forms aggregate indicators that most accurately reflect the state of the object after performing maintenance and scheduled repairs. These new data are necessarily recorded by the system in the plan as an addition to the existing ones, based on which the plan was drawn up in due time.

In short, there is a constant correction of the schedule in the scope of future work, considering the current state of the object. Only the system of maintenance and planned repairs is related to the correction - it makes all the changes and additions on its own, operating with user data and standards from the reference database. It turns out that the duties of the staff include only the execution of the working operations themselves, according to the instructions and their own experience, and a report on the work done in their electronic journal. All other responsibilities are assumed by the maintenance system. The system automatically calculates the time to complete all operations, taking into account their regulations for each and, based on the calculation, indicates the readiness period, selects performers from the staffing table, taking into account their specialization and employment at the time of maintenance, evaluating the volume of current orders according to the schedule and concluded contracts, notifies the personnel - both repairmen and workers in whose operation the facility is located, about the approach of repair work, reserves the necessary materials and parts in the warehouse for them, and monitors that everything is in stock by the beginning of this period.

Download demo version

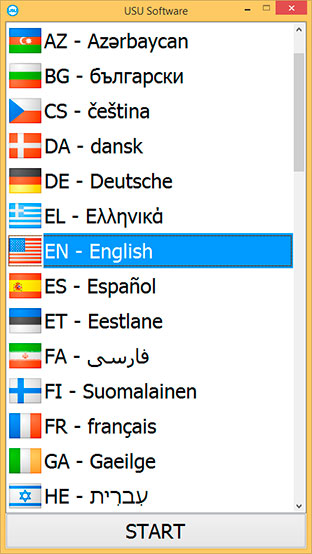

When starting the program, you can select the language.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

The system offers unified electronic forms and one rule to enter information, which simplifies work in it, saves time, and ensures ease of development. The entire volume of current documentation is generated automatically by the deadline set for each document. To complete the task, there is an attached set of forms for every taste. The documents meet all the requirements, have an officially approved format, contain the mandatory details and the company logo, there are a number and date of compilation. The system has a simple interface and easy navigation, which makes it available to users with zero skills, no additional training is required for them.

The system carries out several types of accounting, including statistical and managerial, automatically generates the entire document flow, instantly performs any calculations. The system introduces pop-up windows to support internal communications, clicking on which gives a transition to the subject of discussion mentioned in the window, which is convenient when conducting an agreement. The system provides automatic informing customers about the readiness of work based on data from their order base, where all stages of implementation are automatically recorded.

For external communications, electronic communication is offered - Viber, SMS, e-mail, voice message, all formats are involved in organizing mailings to notify customers. The system keeps the interest of customers through advertising and information mailings in any format - massively, personally, to the target group, and there are text templates for them. At the end of the period, a report is drawn up on the effectiveness of mailings indicating the coverage, the amount of feedback on the number of calls, orders, and the profit received from them.

Order a maintenance and scheduled repair system

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

The program will be installed

If the program is purchased for 1 user, it will take no more than 1 hourBuy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

Maintenance and scheduled repair system

The system integrates with electronic equipment, which improves the quality of operations due to their acceleration and accuracy of execution, optimizes the work of the warehouse and inventory. Such equipment includes a barcode scanner, electronic scales, a data collection terminal, a label printer, video monitoring, and automatic telephone exchange. The system prepares databases in a single format - all participants are brought together in a common list, underneath is a tab bar, where their characteristics, status, standards are presented.

Among the databases there is a range of items, a single database of counterparties in the form of CRM and a database of primary accounting documents, a database of orders, all have their own classifications. The system offers activity planning, based on such plans, the management monitors the employment of users, adds new tasks, and evaluates efficiency.