Operating system: Windows, Android, macOS

Group of programs: Business automation

System of technical repair of equipment

- Copyright protects the unique methods of business automation that are used in our programs.

Copyright - We are a verified software publisher. This is displayed in the operating system when running our programs and demo-versions.

Verified publisher - We work with organizations around the world from small businesses to large ones. Our company is included in the international register of companies and has an electronic trust mark.

Sign of trust

Quick transition.

What do you want to do now?

If you want to get acquainted with the program, the fastest way is to first watch the full video, and then download the free demo version and work with it yourself. If necessary, request a presentation from technical support or read the instructions.

Contact us here

How to buy the program?

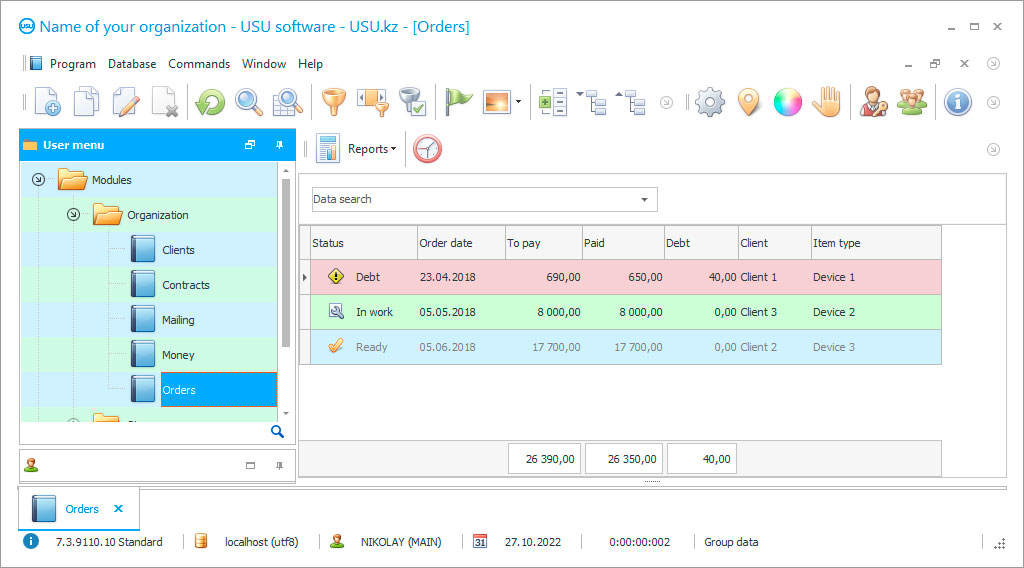

View a screenshot of the program

Watch a video about the program

Download demo version

Compare configurations of the program

Calculate the cost of software

Calculate the cost of the cloud if you need a cloud server

Who is the developer?

Program screenshot

The equipment technical repair system is needed to take a set of measures that allow organizing a timely and effective technical inspection, and, if necessary, equipment repair work, during which the personnel activities are correctly planned. Such a system makes it possible not only to organize technical repair upon emergencies but also to plan a work schedule in the period between repair. It is quite feasible to create such a system and launch its operation, taking into account all the tasks set if there is a special automated installation introduced into the management of an enterprise or department. It is this kind of software that is able to systematize and computerize repair processes and organizing them the procedure. Is there a single challenge for leaders? Make the right choice based on the specifics of your company among many similar programs on the equipment technology market.

The best option for creating a system of technical repair of equipment the USU Software system, which was developed by the USU Software company, with the aim of automating any activity. This program is truly a unique product, as it is capable of monitoring any goods and equipment services, thus, it is universal, suitable for any organization. The convenience of using automation is that it allows shifting many operations associated with calculations, planning, and information processing to automatic devices, almost completely replacing personnel. Plus, you need to take into account that due to the spaciousness of the information base of the system, you can not limit yourself in the amount of data that you process in it, unlike paper accounting forms. One of the most frequently noted advantages by users is the availability of the software installation in terms of self-development. It is so simply formed that even an employee who does not have special skills and similar experience easily understands it and begins to perform duties soon. The floating menu, the visual part of which is customized for each user individually, also facilitates and optimizes the equipment work in computer software.

Who is the developer?

Akulov Nikolay

Expert and chief programmer who participated in the design and development of this software.

2024-05-18

Video of system of technical repair of equipment

This video can be viewed with subtitles in your own language.

Is the main menu divided into just three sections? Yes, there are modules, references, and reports, which, in turn, are also divided into several more subcategories, for more comfortable sorting of equipment information. The basic activity of registering and processing repair requests takes place in the modules section, presented by the developers in the form of multi-tasking extensive accounting tables, whose content and configuration is also easily customizable to the needs of employees. To organize a full-fledged and effective system of technical repair, it is necessary to carefully record tasks with a full description and planning of their resolution. For this purpose, unique entries in the nomenclature are created in the database of each technical application. They are designed so that you can specify such details as full name, the applicant, the date of receipt of the order, the preliminary cause of the breakdown, the results of the initial inspection, the object of repair (devices, technical equipment, etc.), its location or the department responsible for the execution and other parameters that entered based on the specifics of the type of activity-specific enterprise. In some organizations, these details are supplemented by the cost of technical services, if they are produced for a fee. In addition to everything, not only text indicated in the records but also graphic files (photos of the device from a webcam, documents that were previously scanned, any schemes and layouts, etc.) can be attached. A great convenience for working in large companies, with a large number of people involved in receiving and processing applications, is the ability to use the multi-user mode, in which an unlimited number of employees work in the system at the same time, adjusting records and creating new ones, performing various operations, having a connection to a local network or the Internet. In this case, the access of each user to this or that information configured individually, specially appointed by the head administrator. At the same time, the program monitors the simultaneous intervention of several employees in the database and protects the records from corrections made at the same time. This option will allow all members of the repair team to be responsible for the progress of the technical repair of equipment assignments, periodically marking their status in the system by highlighting them in a special color. Also, it possible to make additions to the records, according to the remarks of the technical inspection, or the presence of new facts. If the technical repair requires the purchase of special parts or components, in the program you can directly submit a purchase request to the supply department, which the required employee immediately receives. The software installation the most convenient to use by managers and foremen in the sense that it admits real-time control over the activities of each staff member, tracking the amount of work performed by him, as well as monitoring the timeliness of the execution of technical repair tasks. The scheduler built into the configuration of the automatic application allows forming near future tasks and distributing them among employees, notifying each of them and about their deadline through the system. It should be noted that the software not only keeps records of received and processed applications but also control the available equipment, instruments, tools, overalls, and any other tools used in work processes daily. In the same way, to each position, a special nomenclature record is created, in its specific subcategory, which allows tracking the movement of these items and their use by employees.

In this article, we have described only a small part of the vast number of possibilities that an automated technical repair system of equipment from the USU Software has. To make sure of its multitasking and versatility, as well as to choose a unique configuration according to your business segment, we suggest going to the official USU Software website on the Internet and familiarizing yourself with useful information about the functionality of our software.

Download demo version

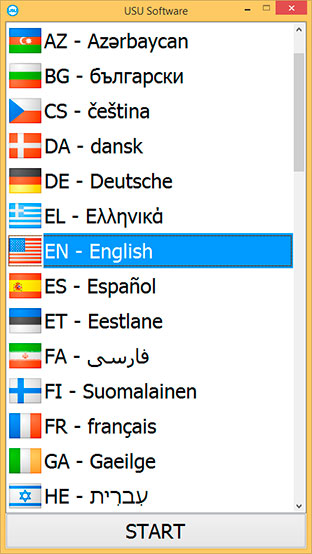

When starting the program, you can select the language.

Who is the translator?

Khoilo Roman

Chief programmer who took part in the translation of this software into different languages.

Whatever equipment the personnel works with, the accounting of its use can be easily organized in the universal system.

Equipment control is carried out in the context of issuance to employees, or by departments, or frequency of use and other management criteria necessary at the moment. Technical tasks are delegated to each employee through the built-in scheduler notification system. Managers keep abreast of all matters, using remote access to the system and its base, even while away from the workplace.

Order a system of technical repair of equipment

To buy the program, just call or write to us. Our specialists will agree with you on the appropriate software configuration, prepare a contract and an invoice for payment.

How to buy the program?

The program will be installed

If the program is purchased for 1 user, it will take no more than 1 hourBuy a ready-made program

Also you can order custom software development

If you have special software requirements, order custom development. Then you won’t have to adapt to the program, but the program will be adjusted to your business processes!

System of technical repair of equipment

To organize the system of technical repair of equipment, a language convenient for the personnel can be used, which makes it possible to use a unique program even abroad. The ability to conduct accounting activities in any convenient language is carried out due to the presence of a built-in language package. Remote access to the informational material of the database can be carried out only if there is a mobile device connected to the Internet.

To greater efficiency and mobility of employees, a special mobile application can be developed for them based on the USU Software system, so that nothing interferes with the prompt processing of applications.

The parameters of the structured tables of the modules section can be customized as you like: you can swap and permanently delete their elements, sort the content of columns, etc. If you already have electronic files of any format, in which the information base on the completed tasks is stored, you can easily import it into the universal system for completeness of accounting. Automation of technical activities can improve the overall efficiency and quality of services provided, as well as improve the quality of service.

To regularly carried out works of the same purpose, you can contain the minimum stock rate of certain parts and spare parts, which can be easily calculated in the reports section. The automatic software monitoring the system of maintenance and repair of equipment installation works without failures and errors. Accounting, carried out through the universal system, is carried out as accurately and transparently as possible, so you do not have to worry about possible audits and other checks. One of the main conveniences in conducting business through a computer application is the easy calculation of piecework wages based on the analysis of the volume of repair work performed.